"new product is out! how does srt's latest sfg-s food-grade fixture achieve high efficiency, high intelligence and high protection?

a new generation of flexible end effectors

born to breakthrough

food manufacturing is an important pillar of the national economy. under the wave of intelligent manufacturing, the transformation of the food industry is imminent. if you are a member of the food industry, have you encountered the following problems:

the production line has a complex operating environment, a variety of skus, and high equipment replacement costs;

·high requirements for timeliness and accuracy, and strong demand for immediate response;

·the labor shortage is high and labor costs are high, and manual sorting cannot break through the production capacity;

food safety problems are difficult to trace, and the cost of testing is high;

seasonal and cyclical centralized production demand is large, and production efficiency needs to be improved immediately;

......

want to turn the food sorting line against the wind

you need a "food grade jig"

not all i-eoats are created equal, what are the most commonly used end tools in food processing?

stainless steel finger/needle

although it is most in line with food safety standards, it is easy to destroy food during the sorting process, and the entry point that cannot be completely closed is an important incentive for bacteria to invade and cause food contamination;

vacuum system

for example, vacuum suction cups are most effective when handling already packaged/protected products, but air backflow is aggravated, and bacteria grow, spread and spread inside the equipment;

adaptive grab system

advances in material science have enabled innovations in design and functionality of i-eoats, which are soft, environmentally adaptable, and contain food-safety systems.

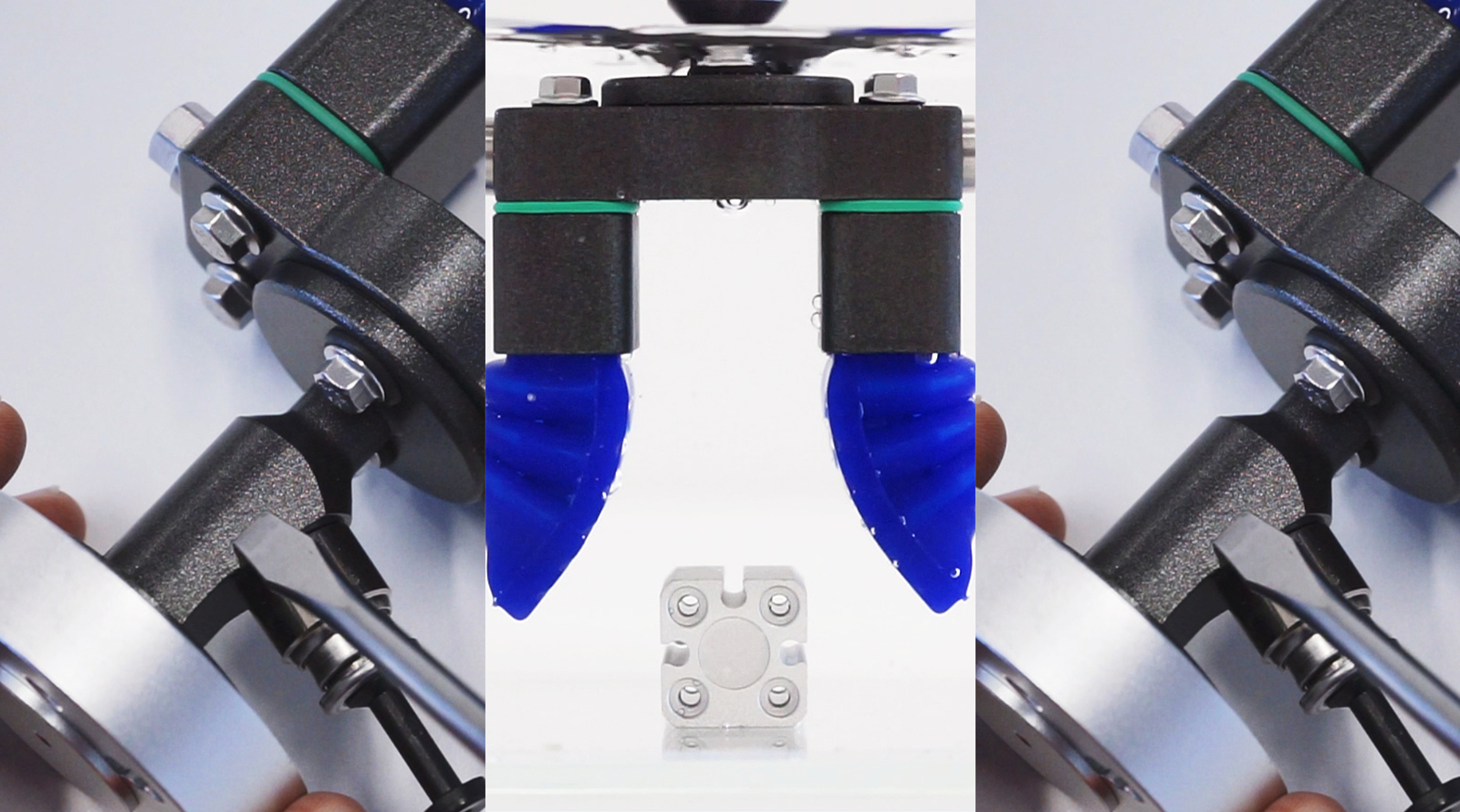

based on the above, srt, relying on its strong r&d strength, has launched a new sfg-s food-grade fixture. sfg-s food grade grips are not only stronger and more durable, but also can be matched as needed, making everything easy and labor-saving everywhere on the food production line.

"food grade" fixtures "civilian" application

make the profession more professional

【model】 sfg-snm2-n4049

【clamp load】 1.2kg

【object size that can be grasped】 0-65mm

[types of objects that can be grabbed] it is suitable for grabbing special-shaped, fragile and easy-to-scratch items;

【environment】 suitable for operation in harsh environments with dust and oil pollution;

[colloid] can be replaced with other colloids of n40 series, n4062, n4075, etc. (can be customized according to actual working conditions).

empowering food safety production

authoritative assists double the application

achieving safety there are skills, of course. the sfg-s food-grade fixture from srt is suitable for all-scenario applications of food production line sorting.

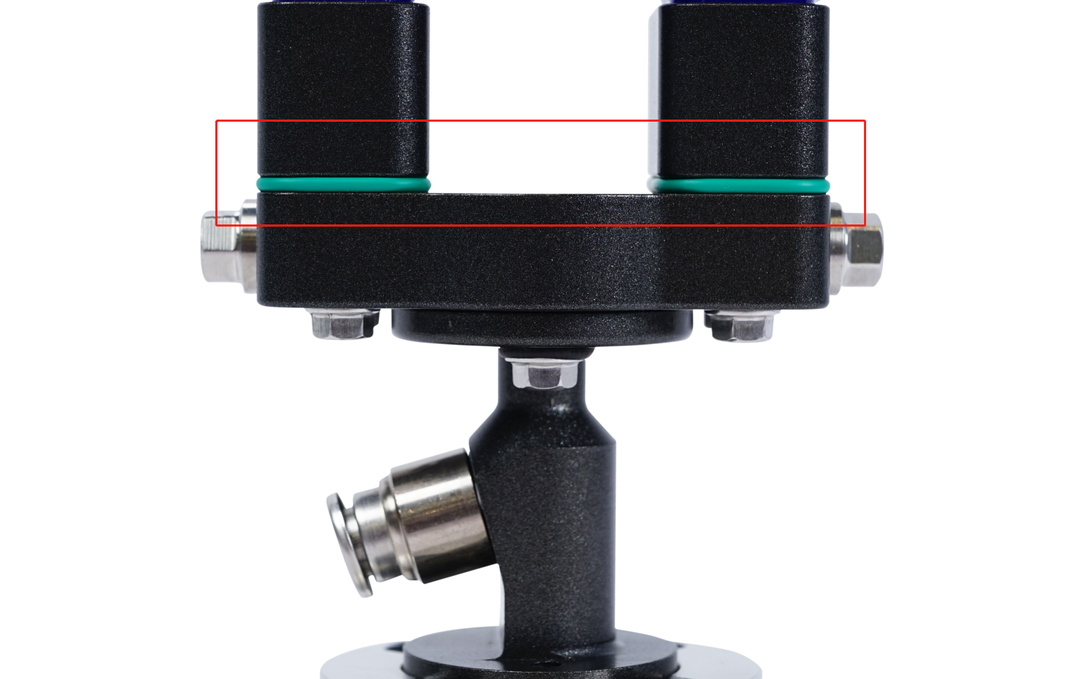

"1" innovation - the surface of the fixture connector is coated with ptfe coating, which makes the fixture have corrosion resistance, good hydrophobicity, non-stickiness and wear resistance

corrosion resistance

it has anti-corrosion effect on neutral detergents, such as mild detergents such as household dishwashing liquid;

hydrophobicity

after encountering water, the water droplets automatically form a ball and do not move;

not sticky

whether it is attacked by ice cream, chocolate chips, sushi (oil stains), soy sauce soup and other stains, just wash it;

abrasion resistance

under the action of mild rubbing external force, the fixture can still maintain its original intact state.

"1" protection - the gaps on the surface of the fixture are all sealed with food-grade fluorine rubber rings to prevent food residues from entering the fixture, and the product has a high level of protection.

"1" breakthrough - the fixture adopts a sanitary design and has the characteristics of "easy maintenance". after the operation, it can be directly washed with a high-pressure water gun. after cleaning, the water vapor condenses into droplets and slides down to prevent liquid accumulation.

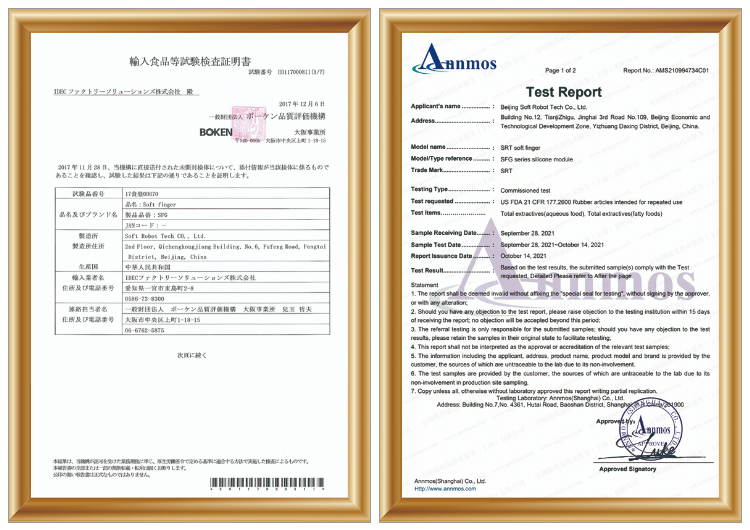

"2" certification - the gripper fingers are made of food-grade silicone, which has passed the us fda testing and japan's jfsl370 two-way testing certification.

sorting standard goods

beginning with appearance and ending with technology

the fixture adopts the classic color matching of srt "cool black royal blue", with turquoise "food grade fluorine rubber seal", the material source is not conservative, showing the quality of ingenuity. in addition, sfg-s food grade clamps also have the following characteristics:

- small size, light weight

- simple installation and easy handling

- more practical, double the combat power

in short, do you want to quickly use "flexible technology" to achieve high quality and high yield? want to completely say goodbye to food safety problems with automated applications? do you want to be the god of food production and reap the double happiness of cost reduction? sfg-s food grade clamps are the first choice.

write at the end

as a "natural talent" in the srt product family, the sfg-s food-grade fixture brings a new technological experience and redefines food production with technology. in the future, more "vanguard" products carrying srt's independent research and development will also flood into all walks of life, and will be empowered by innovative technology to experience the changes of the times.